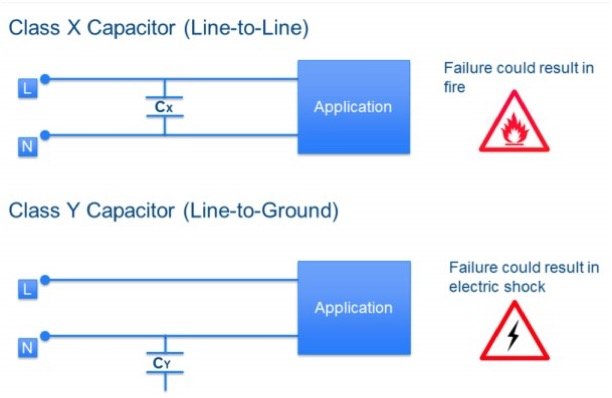

Safety capacitors are divided into x-type and y-type. AC power input is divided into 3 terminals: live wire L/neutral wire N/ground wire G, (L=Line, N=Neutral, G=Ground). Between “L-N”, that is, between “fire wire-neutral wire” is the X capacitor; between “L-G/N-G”, that is, between “fire wire-ground wire or neutral wire-ground wire” is Y capacitance. A capacitor connected between the live wire and the neutral wire is like an “X”, and a capacitor connected between the live wire and the ground wire is like a “Y”. These are not classified according to the material.

X capacitor

Since the location of this capacitor connection is also critical, it needs to meet relevant safety standards. The X capacitor is also one of the safety capacitors. According to actual needs, the capacitance of the X capacitor is allowed to be larger than that of the Y capacitor, but at this time a safety resistor must be connected in parallel at both ends of the X capacitor to prevent the power cord from being damaged due to the charging and discharging process of the capacitor. Cause the power cord plug to be charged for a long time. The safety standard stipulates that when the power cord of the machine at work is unplugged, within two seconds, the charged voltage (or ground potential) at both ends of the power cord plug must be less than 30% of the original rated working voltage.

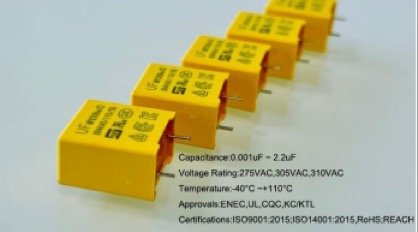

As one of the safety capacitors, X capacitors are required to obtain certification from safety testing agencies. X capacitors are generally marked with safety certification marks and withstand voltage AC250V or AC275V, but their real DC withstand voltage is as high as 2000V or more. When using them, do not use ordinary capacitors with a nominal withstand voltage of AC250V or DC400V as substitutes.

Usually, X capacitors mostly use polyester film capacitors with relatively large ripple currents. This type of capacitor has a large volume, but it allows a large current for instantaneous charge and discharge, and its internal resistance is correspondingly small.

X1Y1 X1Y2 capacitor

The connection position of these two Y capacitors is more critical, and must comply with relevant safety standards to prevent leakage of electronic equipment or electrification of the casing, which may endanger personal safety and life. They are all safety capacitors, which require that the capacitance value cannot be too large, and the withstand voltage must be high. In general, for machines working in subtropical regions, the earth leakage current should not exceed 0.7mA; for machines operating in temperate regions, the earth leakage current should not exceed 0.35mA. Therefore, the total capacity of Y capacitors generally cannot exceed 4700PF

The capacitance of the Y capacitor must be limited, so as to achieve the purpose of controlling the magnitude of the leakage current flowing through it and the influence on the EMC performance of the system under the rated frequency and rated voltage. GJB151 stipulates that the capacity of the Y capacitor should not be greater than 0.1uF. In addition to complying with the corresponding grid voltage withstand voltage, the Y capacitor also requires that the capacitor has sufficient safety margin in terms of electrical and mechanical properties to avoid breakdown and short circuit phenomena under extremely harsh environmental conditions. Protecting personal safety is of great significance. In particular: as a safety capacitor, the Y capacitor must be certified by a safety testing agency. Y capacitors are mostly orange or blue in appearance, and are generally marked with safety certification marks (such as UL, CSA, etc.) and withstand voltage AC250V or AC275V. However, its true DC withstand voltage is as high as 5000V or more. It must be emphasized that the Y capacitor should not be replaced by ordinary capacitors with a nominal voltage of AC250V or DC400V.

Difference between X Capacitor and Y Capacitor

(1) X capacitors suppress differential mode interference, Y capacitors suppress common-mode interference.

(2) Based on the limitation of leak current, the capacitance of the Y capacitor cannot be too large. Generally, the capacitance of the X capacitor is in uF and the Y capacitance is nF.

X capacitors often use metalized polypropylene film capacitors (MPX) resistant to high ripple current. This type of capacitor has a large volume, but it allows a large current for instantaneous charging and discharging, with small internal resistance.

The X capacitor has plastic packages, a square structure, and internal high-voltage OPP material (made by winding metalized polypropylene material). OPP material has a better electrical performance. Also, when the X capacitor made of it in parallel with the input end, the high-frequency pulse interference can be reduced.

Y capacitors often use high-voltage ceramics.

Principle of Safety Capacitor Step-down

The safety capacitor step-down is actually the use of capacitive reactance to limit current. The capacitor actually plays a role in limiting the current, and dynamically distributing the voltage across the capacitor and the load.

Pay attention to the following points when using step-down:

(1) Choose an appropriate capacitor according to the current magnitude of the load and the working frequency of the alternating current, rather than the voltage and power of the load.

(2) Current-limiting capacitors must be non-polar capacitors, and electrolytic capacitors must not be used. And the capacitor withstand voltage must be above 400V. The most ideal capacitor is an oil-filled iron-case capacitor.

(3) Safety capacitors can not be used for high power.

(4) The safety capacitor step-down is not suitable for dynamic load.

(5) When DC is required, half-wave rectification should be used to meet the constant load. Bridge rectification is not recommended.