What are Silicon Carbide (SiC) MOSFETs?

Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistors (SiC MOSFETs) are type of power semiconductor devices that utilizes Silicon Carbide (SiC) as the semiconductor material. Silicon Carbide is a compound composed of silicon and carbon, and offers high thermal conductivity, wide bandgap, and high breakdown voltage. These properties make SiC an ideal choice for high-power and high-temperature applications.

SiC represents the next generation of low-loss semiconductors, aiming to minimize switching losses and enhance performance, particularly in high-temperature conditions. This advancement enables the creation of smaller, lower power, and more efficient power devices compared to traditional silicon counterparts. SiC MOSFETs can reduce switching losses by fast switching due to theoretically no tail-current at switching operation. Low Ron with smaller die size, and low capacitance and gate-charge are achieved.

Structure of SiC MOSFETs

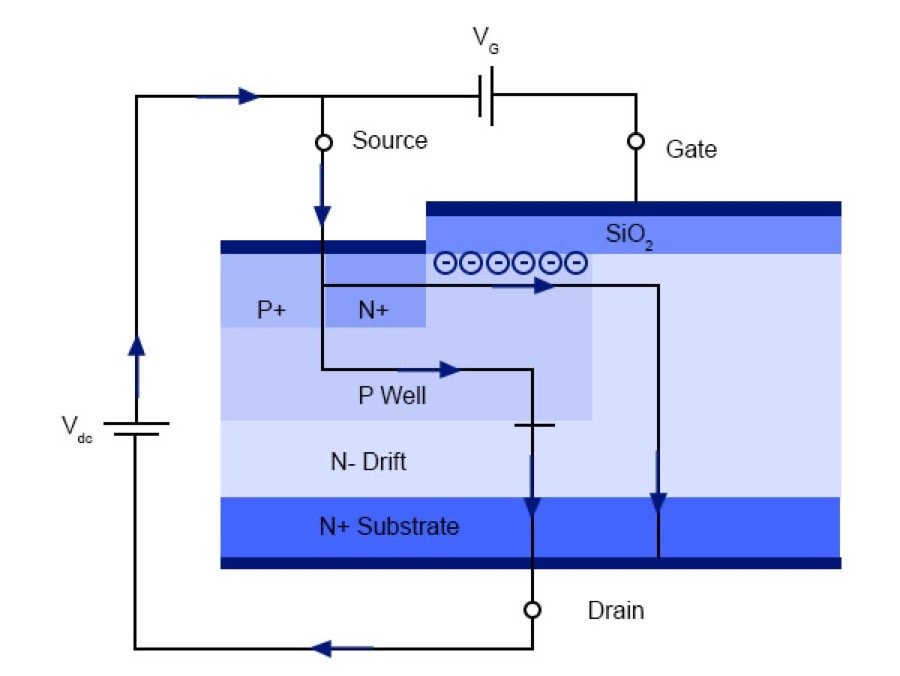

SiC MOSFETs share a similar structure with traditional MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), consisting of three main layers – the source, the gate, and the drain.

- Source: This layer is the source of electrons in the device and is typically connected to the negative terminal of the power supply.

- Gate: The gate is the control terminal of the MOSFET, responsible for switching the device on and off. It controls the flow of electrons from the source to the drain.

- Drain: The drain is the output terminal of the MOSFET, connected to the load in most power electronic applications.

Working Principle

Cross section of SiC MOSFET with equivalent circuit

When a positive voltage is applied to the gate terminal relative to the source, it creates an electric field that attracts electrons, forming a conductive channel between the source and drain terminals, allowing current to flow, making it the “on” state. Conversely, applying zero or negative voltage to the gate turns off the electric field, blocking current flow and placing the SiC MOSFET in the “off” state.

SiC properties and features

SiC is a compound semiconductor material consisting of silicon (Si) and carbon (C). The chemical bond in SiC is extremely strong, and the material is thermally, chemically and mechanically stable. SiC exists in a variety of polymorphic crystalline structures called polytypes, with different physical properties. The 4H-SiC polytype is deemed optimal for use in power devices. The following table compares 4H-SiC with Si and other semiconductor materials that are recently attracting interest.

Features of SiC Power Devices

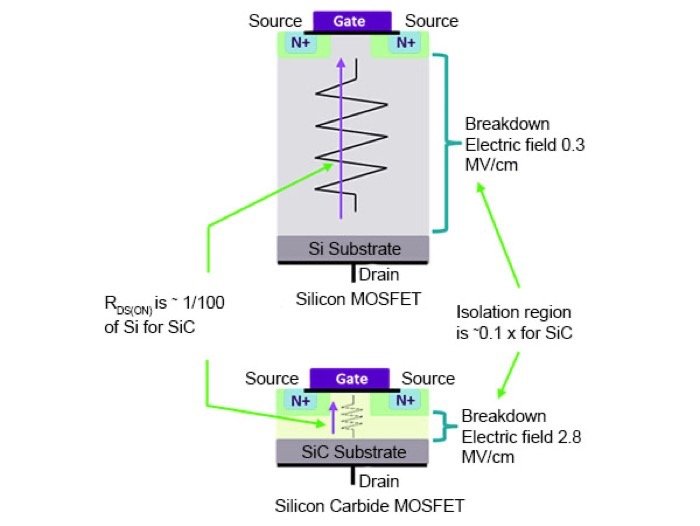

The breakdown electric field strength of SiC is approximately 10 times higher than that of Si, hence the breakdown voltage can reach from 600V to several kilovolts. Doping concentration can be higher than in Si devices, and the drift layer can be made very thin. In high-voltage power devices, almost all of the resistance component is the resistance of the drift layer, and the larger the thickness of the drift layer, the larger the resistance value. When using SiC, it is possible to thin the drift layer, thus enabling the manufacture of devices with extremely low on-resistance per unit area at high voltages. Theoretically, for a certain high voltage, the on-resistance per unit area of the drift layer can be reduced to 1/300 of that of Si.

In Si power devices, IGBTs (Insulated Gate Bipolar Transistors) and other minority carrier devices (bipolar transistors) were mainly used in the past to mitigate the increase in on-resistance accompanying the high breakdown voltage. However, large switching losses cause heating issues, limiting high-frequency operation. By using SiC, it is possible to design fast majority carrier devices such as Schottky barrier diodes and MOSFETs for high voltages, enabling simultaneous achievement of high voltage, low on-resistance, and fast operation, parameters that need to be balanced in silicon devices.

Furthermore, the bandgap is approximately three times larger than that of Si, allowing operation at higher temperatures than Si devices. Currently, due to limitations in package thermal resistance, ensuring operation temperatures between 150°C and 175°C is feasible, but with advancements in packaging technology, ensuring operation temperatures of 200°C and above will also become possible.

The rear side of the SiC MOSFET package is insulated.

The current packaging of our SiC MOSFET has electrodes exposed and is not insulated on the back when viewed from the marked side. The back side is connected to the drain. The drain has a high voltage. When attaching a radiator plate connected to the ground, be careful that this portion (red circular mark) does not also come into contact with the peripheral components.

FAQs

Q1: What is the difference between MOSFET and SiC MOSFET?

Answer: SiC MOSFET stands for silicon carbide metal-oxide-semiconductor field-effect transistor. Unlike IGBTs, which are controlled by current applied to the gate terminal, MOSFETs are voltage-controlled, with their operation determined by the voltage applied to the gate terminal.

Q2: What are the advantages of SiC MOSFETs?

Answer: SiC devices provide lower on-state resistance and off-state leakage currents compared to silicon counterparts, resulting in enhanced efficiency. Additionally, they exhibit very low or negligible reverse-recovery current and can operate at three to five times higher system frequencies. This capability reduces the size and weight requirements of capacitors and magnetics.

Q3: What are the disadvantages of SiC MOSFETs?

Answer: Doping in SiC fabrication poses challenges due to its chemical inertness, physical strength, and low diffusion coefficient of impurities. Current manufacturing processes for SiC substrates yield various types of material defects.

Q4: Why is SiC more efficient?

Answer: Reduced Switching Losses: SiC boasts superior switching characteristics, facilitating faster switching speeds and minimized energy losses during operation. This leads to enhanced efficiency and diminished heat generation.

Q5: What are the applications of SiC MOSFETs?

Answer: SiC (Silicon Carbide) MOSFETs find application in various high-performance and high-power electronic systems.

Some key applications include: Power Electronics, Aerospace and Defense, Renewable Energy, Telecommunications, Medical Equipment, traction inverters, motor drives, photovoltaic solar inverters, and DC-DC converters

For further question or inquiries, please kindly contact Loie: sales4@topdiode.com, or visit our website: www.topdiodes.com thanks