SiC MOSFETs vs. Silicon Si MOSFETs

Silicon-carbide-based (SiC) MOSFETs allow for much greater efficiency levels compared to silicon-based (Si) versions, although it is not always easy to decide when this technology is the better choice. We explain which criteria are to be considered here. For voltages over 1000V, IGBTs were usually the solution of choice. But the superb properties of SiC now enable fast-switching, unipolar components that can be used in place of bipolar IGBTs. They enable applications that were previously only feasible at lower voltages (<600V) to now be implemented at higher voltages. Compared to bipolar IGBTs, these SiC-based MOSFETs offer power loss reductions of up to 80%.

As a wide-bandgap (WBG) semiconductor material, SiC’s wider energy difference allows it to have higher thermal and electronic properties compared to traditional silicon. This characteristic enables power devices to operate at higher temperatures, frequencies, and voltages.

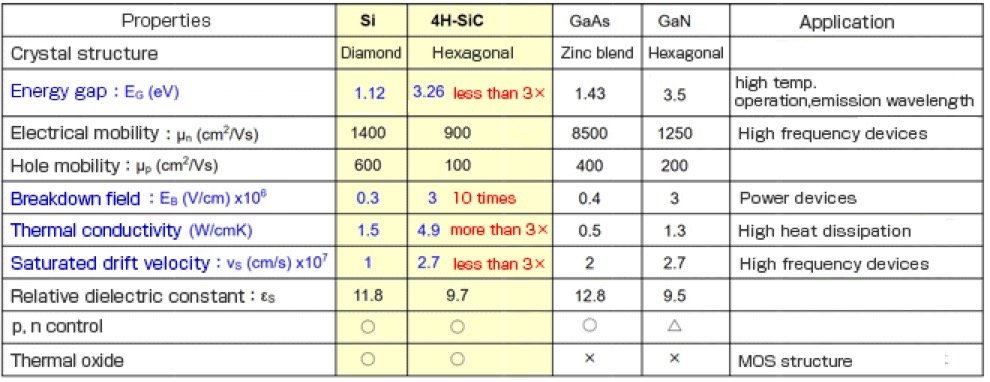

The yellow-highlighted part of the table compares Si and SiC. Characteristics and values in blue are parameters that are particularly important for uses in power devices. As the numerical values indicate, where these parameters are concerned SiC is superior. And in contrast with other new materials, but similarly to Si, a feature of SiC is the ability to control the p-type and n-type regions necessary for device fabrication over wide ranges. For these reasons, SiC is anticipated to be a material for use in power devices that go beyond the limits of Si.

Silicon Carbide (SiC) MOSFETs Vs Silicon (Si) MOSFETs

The selection between SiC MOSFETs and Si MOSFETs hinges on the specific demands of the application. SiC MOSFETs shine in high-power, high-temperature, and high-frequency scenarios where efficiency and thermal management are paramount. Conversely, Si MOSFETs are well-suited for lower voltage and more versatile applications. A detailed comparison of their disparities is provided in the table below:

| Parameters | Silicon Carbide MOSFETs | Silicon MOSFETs |

| Semiconductor Material | Silicon Carbide (SiC) | Silicon (Si) |

| Bandgap | Wide bandgap (Approx 3.3 eV) | Narrow bandgap (Approx 1.1 eV) |

| On-Resistance | Low on-resistance resulting low conduction losses | High on-resistance resulting high conduction losses |

| Switching Speed | Fast switching speed | Slow switching speed |

| Switching Loss | Low switching loss | High switching loss |

| Thermal conductivity | High thermal conductivity | Low thermal conductivity |

| Efficiency | High efficiency | Low efficiency |

| Voltage Rating | Suitable for high voltage applications | Suitable for low voltage applications |

| Applications | EV, renewable energy, high-frequency converters, aerospace, industrial drivers | General-purpose electronics, low to moderate power applications |

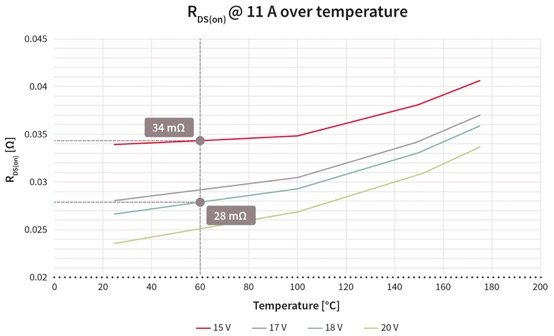

Compared to Si MOSFETs, SiC provides a much more stable

RDS(on) over its operational temperature range. Whereas Si MOSFETs are usually promoted with their

maximum RDS(on) at 25°C, SiC MOSFETs highlight their typical value at 25°C together with a gate drive

voltage (typically 18 V) and at a specific current (ID). A typical CoolMOS device can suffer an expected 1.67

In addition, while Si MOSFET is generally commercialized only up to about 1000V, SiC MOSFET is commercialized up to about 3300V because it can

keep on-resistance low even at high withstand voltages.

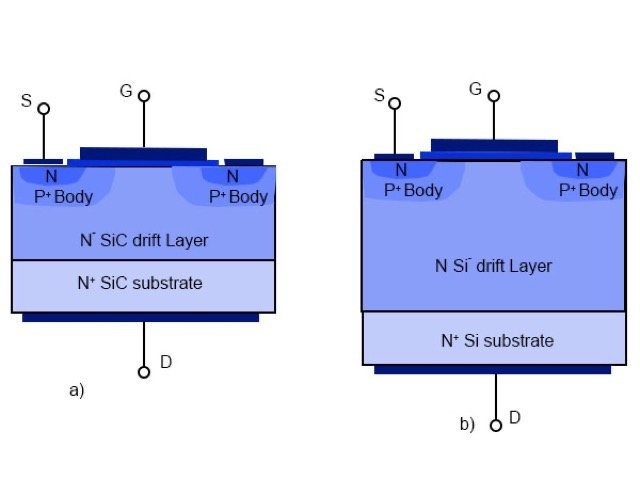

SiC can realize MOSFET, the unipolar device that operate only with electronics even in high-voltage products, and the

turn-off loss is smaller than bipolar devices because no tail current is generated. For this reason, SiC MOSFET is

attracting attention because it can operate in the high switching frequency, which was difficult for Si IGBT, and has a

great advantage of contributing to the miniaturization of passive components, making it ideal for power converting

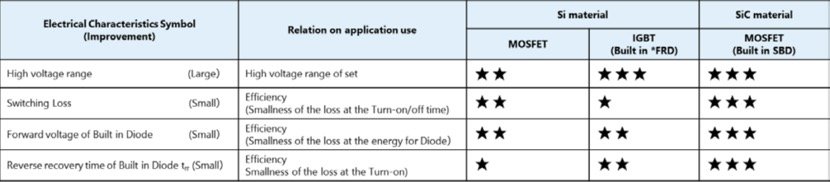

If Si IGBT replaced with SiC MOSFET, what will change?

By replacing Si IGBT with SiC MOSFET, it is possible to reduce the size and weight of the euipments due to highfrequency operation, and to achieve highly efficient power conversion. The compared images of Si MOSFET/IGBT and SiC MOSFET characteristics are shown in below table.

FAQs

Q1: What is the advantage of SiC MOSFET over Si MOSFET?

Answer: At low voltages and moderate power levels, Si-MOSFETs with low R(ON) can incur lower conduction losses compared to IGBTs. Moreover, SiC and GaN materials exhibit significantly higher critical breakdown voltages than silicon, enabling thinner drift layers and higher doping concentrations

Q1: Why do we use silicon in MOSFETs?

Answer: The silicon dioxide forms the gate of the mosfet. It is used to provide isolation by averting the direct flow of charges on gate to the conducting channel. It is also a good dielectric material.

Q3: Why is SiC better than silicon?

Answer: SiC (silicon carbide) is a compound semiconductor composed of silicon and carbide. SiC provides a number of advantages over silicon, including 10x the breakdown electric field strength, 3x the band gap, and enabling a wider range of p- and n-type control required for device construction.

Q4: What is the difference between SiC and Si semiconductors?

Answer: As a wide-bandgap (WBG) semiconductor material, SiC’s wider energy difference allows it to have higher thermal and electronic properties compared to traditional silicon. This characteristic enables power devices to operate at higher temperatures, frequencies, and voltages

Related reading:What are Silicon Carbide (SiC) MOSFETs?

For further question or inquiries, please kindly contact Loie: sales4@topdiode.com, or visit our website: www.topdiodes.com thanks