Si IGBT has been the leader in the market for some time. However SiC Mosfets are taking over some application where is much better. In the Automotive industry with the development of new Electric Cars, SiC Mosfet are getting a lot of attention.

What are Si IGBTs and SiC MOSFETs?

Si IGBT is shorthand for silicon-insulated-gate bipolar transistors. SiC MOSFET is short for silicon carbide metal-oxide-semiconductor field-effect transistor.

Si IGBTs are current-controlled devices that are toggled by a current applied to the gate terminal of the transistor, while SiC MOSFETs are voltage-controlled by a voltage applied to the gate terminal.

The primary difference between Si IGBTs and SiC MOSFETs is the type of current that they can handle. Generally speaking, MOSFETs are suited for high frequency switching applications, while IGBTs are better suited for high-power applications.

Silicon Carbide Mosfet vs Silicon IGBTs

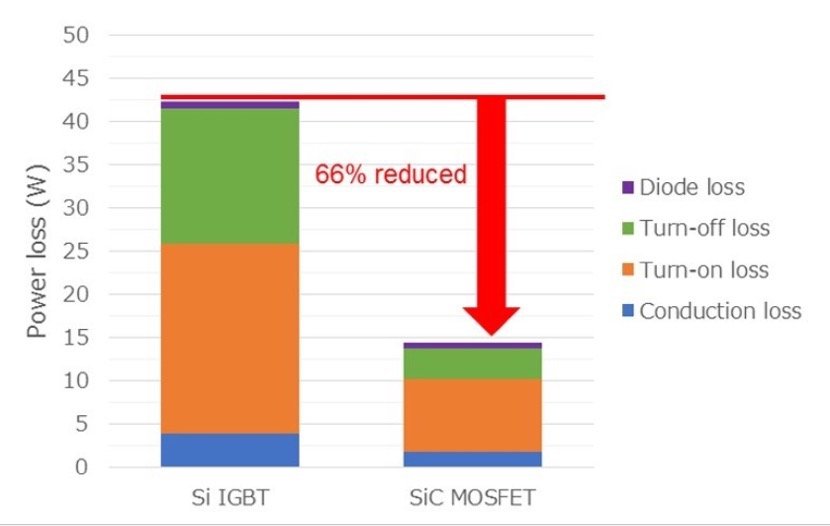

Following figure shows a comparison between two devices for a similar Power level:

Why silicon IGBTs and silicon carbide MOSFETs are essential in motor drive applications

Electric motors power many modern technologies, and battery systems are a common power source. Electric vehicles (EVs) use large batteries that provide direct current (DC) electricity to power AC electric motors, enabling movement. Absolute control of these AC motors is essential to the performance and efficiency of the vehicle, as well as the safety of those inside. However, this powertrain system relies on inverters to convert the DC power from the battery into an AC signal that the motors can use to create motion.

These inverters precisely control the motor’s speed, torque, power, and efficiency and enable regenerative braking capabilities. Ultimately, the inverter is as valuable to the powertrain system as the motor. As is true with all devices in power applications, inverters can vary drastically in capabilities and design requirements and are essential to the overall system performance of DC power to AC motor system.

Two types of inverters are used in modern DC to AC motor drive applications: silicon IGBTs and silicon carbide MOSFETs. Historically, Si IGBTs are the most common, but SiC MOSFETs have multiplied in popularity given their various performance advantages and continually dropping costs. When SiC MOSFETs first came onto the market, they were widely cost-prohibitive for most motor drive applications. However, as the adoption of this superior technology increases, scaled manufacturing has dramatically reduced the cost of SiC MOSFETs.

SiC MOSFETs advantages vs. Si IGBT

・The on-resistance characteristic of SiC-MOSFET Vd-Id characteristics changes linearly, and SiC-MOSFETs have an advantage over IGBTs at low currents.

・Switching losses of SiC-MOSFETs can be greatly reduced compared with IGBTs.

SiC MOSFETs are more resistant to thermal runaway. Silicon carbide is more thermally conductive, allowing for better device-level heat dissipation and stable operating temperatures. SiC MOSFETs are better suited for warmer ambient condition spaces such as automotive and industrial applications. Additionally, given their thermal conductivity, SiC MOSFETs can eliminate the need for additional cooling systems, potentially reducing the overall system size and potentially reducing system cost.

Because SiC MOSFETs operate at much higher switching frequencies than Si IGBTs, they are ideal for applications where accurate motor control is essential. High switching frequencies are paramount in automated manufacturing, where highly accurate servo motors are used for tool arm control, precision welding, and precise object placement.

In addition, a notable advantage of SiC MOSFET over Si IGBT motor driver systems is their ability to be embedded within motor assemblies, with a motor controller and inverter embedded within the same housing as the motor.

By moving the motor driver assembly to the local location of the motor, the cabling between the drive inverters and the motor driver can be drastically reduced, enabling significant savings. In the example from Image B, a traditional Si IGBT power cabinet may require 21 unique cables to power the seven motors (labeled ‘M’) of the robotic arm, which could amount to hundreds of meters of expensive and complex cabling infrastructure. With a SiC MOSFET motor drive system, the cable count can be reduced to two long cables that connect to each of the motor’s motor drives within the local motor assembly.

Improved inverter technology with silicon carbide MOSFETs

Silicon carbide MOSFETs have drastically improved inverter technology for motor drive systems. As is true with all types of components, there are particular applications where IGBTs may still be better suited. However, SiC MOSFET inverters offer several distinct advantages over Si IGBTs, making them very attractive solutions for motor drive applications and a wide array of other applications.

Browse an assortment of MOSFETs and IGBTs from industry-leading manufacturers at Arrow.com. Find popular and top-selling MOSFET and IGBT transistor products below.

For further question or inquiries, please kindly contact Loie: sales4@topdiode.com, or visit our website: www.topdiodes.com thanks