Application of Topdiode IGBT, Driver IC – Home Appliance Field

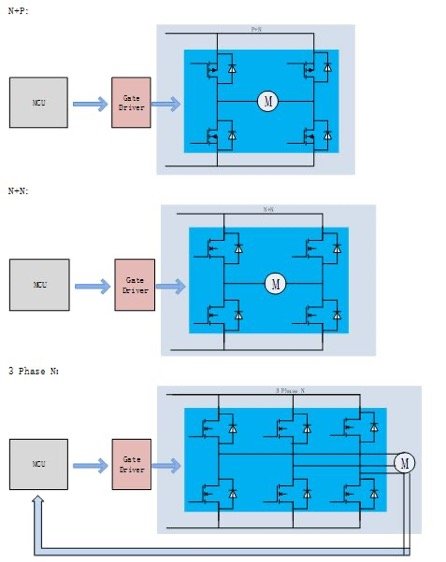

The brushless DC fan is a DC motor without mechanical commutator and brushes. It uses an electronic commutation device, thus overcoming the shortcomings of general DC motors such as commutation sparks, poor reliability, high noise, and radio interference. . It not only has the mechanical characteristics and adjustability of general DC motors, but also has the advantages of wide speed range, small size, quick start, reliable operation, high efficiency and long life. Currently widely used in the small household appliance fan industry, the general power is less than 100W. The topology structures include P+N, N+N, and 3 Phase.

Advantages to use Topdiode Mosfet, Drive IC on Fans:

Smaller package size: dual-chip N+N or N+P dual-core package chip for brushless brushless DC motors.

Greater current capability: The use of CLIP and SMD packaging makes the chip’s heat dissipation capability stronger.

Better reliability: greater avalanche capability and impact resistance.

Topdiode Mosfet, Drive IC used on BLDC fan

Complementary MOSFET:VDS=12V-60V P+N double chips

Dual N and P-channel MOFET:VDS=18V-60V N+N double chips

IC:driver IC

Topdiode mosfet,drive IC used on Robot Vacuum Cleaner

The basic structure of a robot vacuum cleaner usually includes a central processor, power/battery management unit, battery charger, wireless communication module, human-machine interface, sensors and drive modules (brush and brushless motors). As the market and application requirements further improve, motor drive and lithium battery management are also developing in the direction of high power density, miniaturization, and long continuous working time.

Firstly, power devices are required to be reliable, efficient and energy-saving. Secondly, new packaging shapes are required to achieve smaller size. Small design is also very important.

TOPDIODE Super Trench MOSFET series products can achieve high-frequency switching (low Rg), low conduction loss (optimal RDSon performance), low switching loss (excellent switching characteristics), and cooperate with advanced packaging technology to improve the performance of MOSFET devices in power conversion System efficiency and power density in the process, while ensuring shock resistance during the switching process in harsh environments, achieving fast, smooth, and efficient power management and motor control.

Topdiode mosfet,drive IC used on Robot Vacuum Cleaner:

AC/DC charger MOSFET:

SJ-III MOSFET:VDS=650V-700V Ron@10V(max)=900mΩ-2400mΩ

channel SGT-II MOSFET & N-channel SGT-I MOSFET:VDS=100V-150V

Ron@10V(max)<10mΩ

Complementary MOSFET:VDS=12V-30V P+N double

Dual N and P-channel MOSFET:VDS=18V-30V N+N double

IC:DRIVE IC

N-channel SGT-II MOSFET & N-channel SGT-I MOSFET:VDS=30V

Ron@10V(max)=2.3mΩ-7.1mΩ

BATTERY CHARGE and Discharge MOSFET:

N-channel Trench MOSFET:VDS=30V Ron@10V(max)<11mΩ

N-channel SGT-II MOSFET & N-channel SGT-I MOSFET:VDS=30V Ron@10V(max)<10mΩ

Topdiode 1200V-1350V IGBT used on Induction Cooker

As the market trend moves toward fast cooking, which has become a new highlight, fast cooking requires induction cookers with higher power and efficiency, which also means that components must work under more demanding conditions. Faster, more even heating and greater energy efficiency make induction cooking a growing consumer trend. But designing an induction cooking system is not without its challenges.

Designers often face the problem of high on-site failure rates caused by power grid disturbances, and the replacement and repair costs of stoves are very high. On the other hand, the competitive nature of the market increases cost pressure and limits the application of protection functions.

TOPDIODE Trench FS II IGBT series products have the characteristics of low saturation voltage, small switching loss, high power density, small switching oscillation, and high parameter consistency, providing you with more cost-effective products.

Topdiode 1200V-1350V IGBT used on induction cooker

1200V-1350V IGBT: VCE=1350V, ID=15A/25A/40A

Topdiode mosfet used on Food Processor/Blender

Topdiode IGBT Mosfet used on Kitchen Hood

In recent years, the frequency conversion technology of kitch smoke exhauster has gradually matured. Compared with ordinary AC motor hoods, the biggest difference of DC motor hoods is that DC motor hoods are more energy-saving, more efficient, and have low noise. The full voltage of DC variable frequency motor hoods is The efficiency of 32% is much higher than the national standard of 25%, and the energy saving is more than 30% year-on-year.

In addition, due to the environmental problems in Chinese-style kitchens, new tests have been put on the motor performance of range hoods. Grease is formed between the stator and rotor of traditional fixed-frequency motors, which causes the motor to generate heat, which greatly reduces the service life. DC frequency conversion The motor hood has better sealing. Under the action of the frequency conversion controller, it can ensure that the voltage and current parameters of the hood are more accurate, thereby extending the overall service life of the hood.

In response to market development, TOPDIODE has launched a new generation of Trench FS II IGBT series products, which have the characteristics of low saturation voltage, small switching loss, high power density, small switching oscillation, and high parameter consistency, making the system operate stably and smoothly while suppressing vibration, bringing less noise

Topdiode IGBT Mosfet used on kitch smoke exhauster

SJ-III MOSFET:VDS=650V-700V Ron@10V(max)=360mΩ-1100mΩ

IGBT:

VCE=600V-1200V ID=7A-40A

PIM:1200V less than 200A

Topdiode mosfet used on Vacuum Cleaner

The vacuum cleaner is a common cleaning tool in modern households that combines sweeping and vacuuming functions. The power part of a vacuum cleaner mainly includes a vacuum cleaner motor and a brushless motor controller. The fan impeller of the vacuum cleaner is driven by the motor at high speed, and the air in the impeller is quickly discharged from the fan. At the same time, the air in the vacuum cleaner is continuously replenished into the fan, and the dust and dirt are sucked into the cavity with the dust sweeping brush. The power of portable vacuum cleaners is generally below 250W.

TOPDIODE Super Trench MOSFET series products can achieve high-frequency switching (low Rg), low conduction loss (optimal RDSon performance), low switching loss (excellent switching characteristics), and cooperate with advanced packaging technology to improve the performance of MOSFET devices in power conversion System efficiency and power density in the process, while ensuring shock resistance during the switching process in harsh environments, achieving fast, smooth, and efficient power management and motor control.

AC/DC charger MOSFETS:

SJ-III MOSFET:VDS=650V-700V Ron@10V(max)=140mΩ-680mΩ

Synchronous rectification MOSFET:

SGT-II MOSFET & SGT-I MOSFET:VDS=100V-150V Ron@10V(max)<10mΩ

Motor drive:

SGT-II MOSFET & SGT-I MOSFET:VDS=40V Ron@10V(max)=1mΩ-6.6mΩ DFN5*6

SGT-II MOSFET & SGT-I MOSFET:VDS=60V

Ron@10V(max)=3.1mΩ-7.5mΩ DFN5*6

Battery charge and discharge:

SGT-II MOSFET & SGT-I MOSFET & N-channel Trench MOSFET:

VDS=40V Ron@10V(max)=1mΩ-6.6mΩ DFN5*6

VDS=60V Ron@10V(max)=3.1mΩ-7.5mΩ DFN5*6

Complementary MOSFET:VDS=12V-30V P+N double

Dual N and P-channel MOSFET:VDS=18V-30V N+N double

IC:drive IC