650V 15A Silicon Carbide (SiC) Schottky Diode with TO-263 Package TPDG15S65C1P Topdiode (AIDK16S65C5)

- Zero Reverse Recovery Current

- Temperature-Independent Switching Behavior

- Extremely Fast Switching

- Positive Temperature Coefficient on VF

- Low Switching Losses

- Higher Efficiency

Topdiode 650V 15A Silicon Carbide (SiC) Schottky Diode with TO-263 Package TPDG15S65C1P (AIDK16S65C5)

TOPDIODE TPDG15S65C1P is an ultrahigh performance power Schottky diode designed for high frequency applications where high efficiency and high reliability are required. The wide band gap material

allows the design of a Schottky diode structure with lower leakage current and conduction losses.

Topdiode TPDG15S65C1P is a nice alternative offer for Infineon SiC Schottky barrier diodes IDK12G65C5.

Topdiode 650V 15A Silicon Carbide (SiC) Schottky Diode with TO-263 Package TPDG15S65C1P

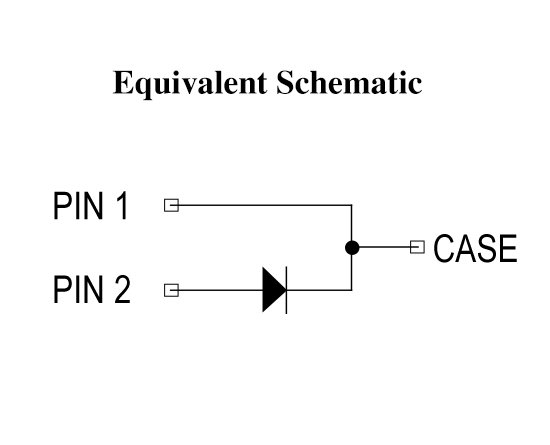

- Tab

| Topdiode PN | TPDG15S65C1P |

| Description | SIC SBD |

| IFSM(A) | 100A |

| IF(AV) | 15A@149℃ |

| Vds | 650V |

| Package | TO-263 |

| Cross to Brand | Infineon |

| Pin to Pin Cross P/N | AIDK16S65C5 |

Topdiode Hot Selling Products (6)

SiC Schottky Barrier Diode Datasheet

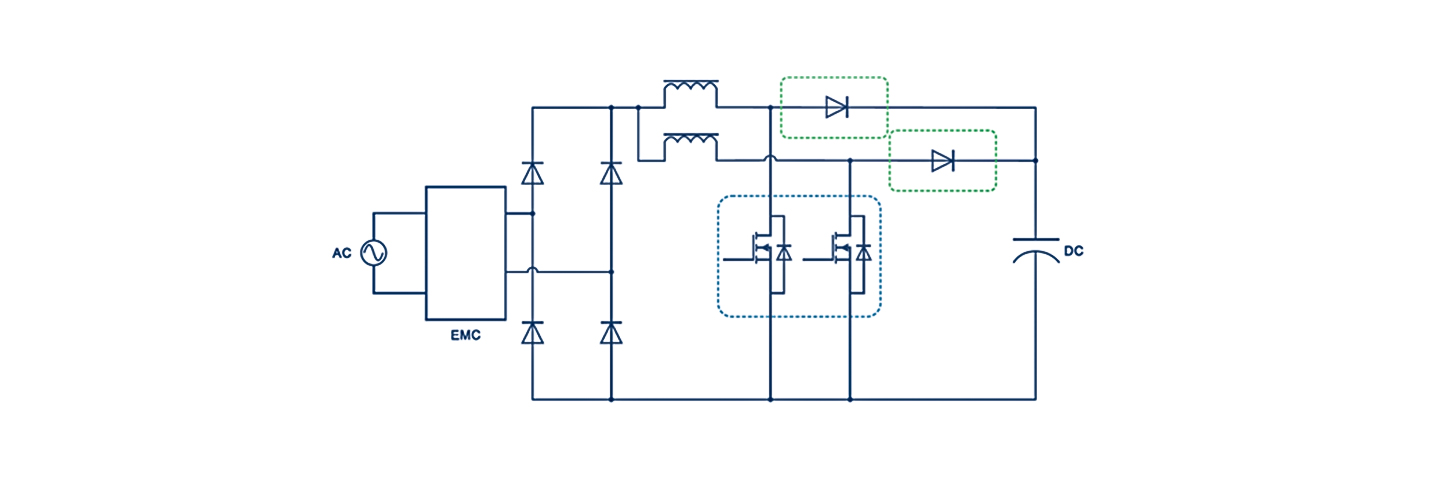

Topdiode SiC Schottky Barrier Diode Used on UPS (Server Power Supply)

The efficient use of electrical energy has evolved from a goal to a necessity as power-hungry consumer sectors experience exponential growth. Designers are abandoning outdated silicon solution and switch to Silicon Carbide SiC to gain system-level efficiencies with smaller, lighter and better thermal performance include LED lighting , USB Charger and Home appliance.

Topdiode Recommended Products:

SiC Diode:TPDA10S65C1P

Topdiode Silicon Carbide (SiC) Schottky Diode Applications

Silicon carbide (SiC), a semiconductor compound consisting of silicon (Si) and carbon (C), belongs to the wide bandgap (WBG) family of materials. Its physical bond is very strong, giving the semiconductor a high mechanical, chemical and thermal stability. The wide band gap and high thermal stability allow SiC devices to be used at junction temperatures higher than those of silicon, even over 200°C. The main advantage offered by silicon carbide in power applications is its low drift region resistance, which is a key factor for high-voltage power devices.

Silicon Carbide Schottky Barrier Diodes are semiconductor devices that consist of a metal contact on a layer of n-type Silicon Carbide (SiC) material. The metal contact forms a Schottky barrier with the SiC material, which allows the flow of current in only one direction. SiC Schottky barrier diodes offer several advantages over conventional diodes, including lower forward voltage drop, shorter reverse recovery time, higher breakdown voltage, and higher temperature operation

The working principle of a Silicon Carbide (SiC) Schottky diode is based on the metal-semiconductor junction known as the Schottky barrier. When a metal (typically aluminum or platinum) is deposited on a SiC substrate, a Schottky barrier is formed between the metal and the semiconductor material. Unlike traditional P-N junction diodes, the Schottky diode does not have a depletion region, which leads to a lower forward voltage drop and faster switching speed.

In forward bias, the metal contact is connected to the positive terminal of a voltage source, while the SiC substrate is connected to the negative terminal. When a positive voltage is applied, the electrons from the metal contact are injected into the SiC substrate, resulting in a flow of current through the device. The forward voltage drop in a SiC Schottky diode is typically lower than in a traditional P-N junction diode, which leads to lower power losses and higher efficiency.

In reverse bias, the metal contact is connected to the negative terminal of a voltage source, while the SiC substrate is connected to the positive terminal. When a negative voltage is applied, the Schottky barrier width increases, and the electric field across the device increases, leading to a breakdown of the device at a certain voltage, known as the reverse breakdown voltage. The reverse breakdown voltage of SiC Schottky diodes is typically higher than in traditional P-N junction diodes, which makes them suitable for high-voltage applications.

SiC Schottky diodes are used in a wide range of high-performance applications that require high temperature and high voltage operation, low power losses, fast switching speeds, and high efficiency. Some common applications of SiC Schottky diodes include:

Power Electronics: SiC Schottky diodes are used in power electronics applications, such as in switch-mode power supplies (SMPS), inverters, and motor drives. They help to reduce power losses, increase efficiency, and improve power density.

Automotive: SiC Schottky diodes are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) to improve efficiency and extend the range. They are also used in battery chargers, DC-DC converters, and onboard chargers.

Aerospace and Defense: SiC Schottky diodes are used in aerospace and defense applications, such as in power supplies, motor drives, and electronic control units (ECUs). They help to reduce the weight, size, and complexity of the systems while improving reliability and performance.

Renewable Energy: SiC Schottky diodes are used in renewable energy systems, such as solar inverters and wind turbines. They help to improve efficiency, reduce the system cost, and increase the power density.

Consumer Electronics: SiC Schottky diodes are used in consumer electronics applications, such as laptops, smartphones, and tablets. They help to improve the battery life, reduce the charging time, and increase power efficiency.

Our SiC Schottky Barrier Diodes (SBDs) increase efficiency and add superior reliability in high-voltage applications. SiC diodes exhibit higher breakdown voltage with a lower forward voltage drop and a significantly shorter reverse recover time. SiC SBDs are designed with balanced surge current, forward voltage, thermal resistance and thermal capacitance ratings at low reverse current for lower switching loss, enabling more efficient power systems.